Real-time monitoring of additive manufacturing processes using laser-ultrasonic technology: potential and promising results

Additive manufacturing (AM), also known as 3D printing, has become increasingly prevalent in industries such as aerospace, medical, and automotive. However, in order to ensure that parts and components are produced to meet specific specifications, it is necessary to monitor the manufacturing process and detect any deviations as soon as possible, in realtime. One technology that has been proposed for such purpose is laser-ultrasonic technology.

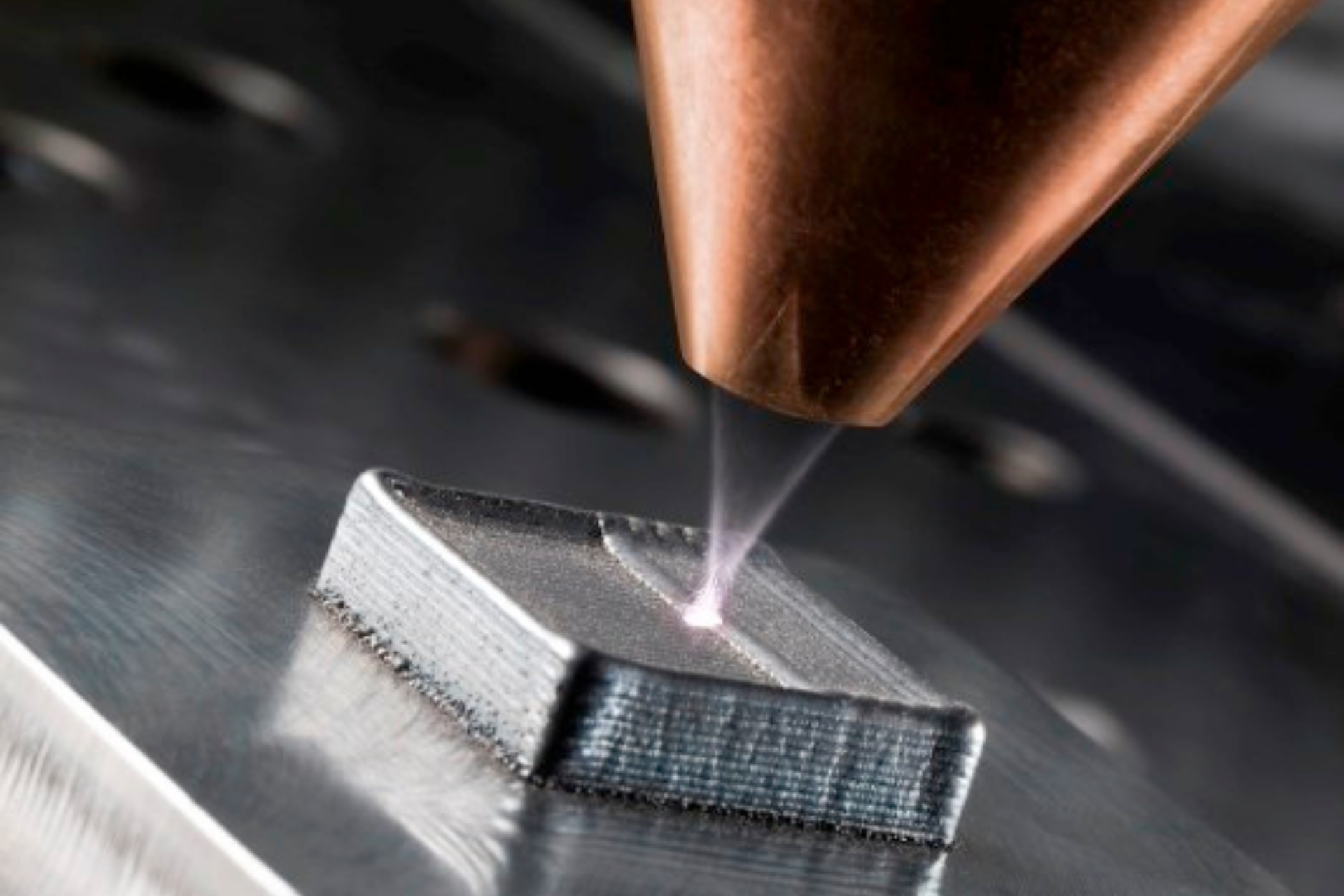

Despite being in its early stages of development, laser-ultrasonics has demonstrated significant potential for monitoring AM manufacturing processes. For instance, the CEA-List group, under the leadership of Jerome Laurent, has published a video showcasing their results using Tecnar’s Lus Ultimate, see below. By analyzing the frequency content of the laser-ultrasonic signal, they were able to detect defects in realtime as the manufacturing process occurred. The laser-ultrasonic is installed directly inside the AM cell.

Laser-ultrasonics has the potential to revolutionize the way we monitor additive manufacturing processes, improving quality control, and reducing waste. While still in its early stages of development, the results thus far have been promising, and we can expect to see further advancements in the near future. Numerous research groups, especially in China, are actively working on its development. We will continue to follow their progress and publish their results on this site.