Advancing Cold Spray Additive Manufacturing with Laser-Ultrasonics

By Daniel Levesque, Christophe Bescond, and Cristian Cojocaru

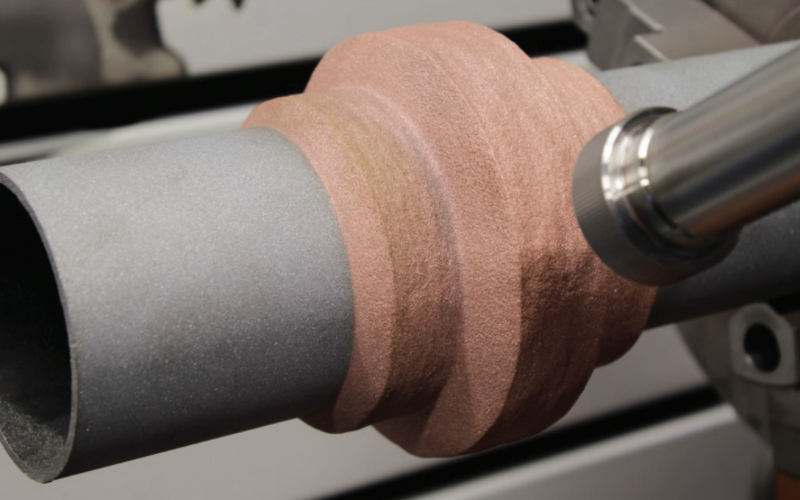

In recent years, the application of laser-ultrasonics in cold spray additive manufacturing (AM) has gained significant attention, especially for its role in enhancing the quality control of complex metallic parts. Cold spray is a solid-state coating technology known for its high deposition rates, making it suitable for large-scale AM applications. However, quality control remains a challenge.

The paper “Laser-ultrasonic inspection of cold spray additive manufacturing components” by Dr. Daniel Levesque et al provides a comprehensive review of the use of laser-ultrasonics in inspecting cold spray-manufactured parts. This non-contact technique is especially attractive for online implementation, offering precise detection of flaws during the additive manufacturing process. The paper explores several methods used to inspect cold spray samples. Key findings include the use of laser-ultrasonics to detect porosity and flaws in the cold-sprayed layers. The synthetic aperture focusing technique (SAFT) proved effective in reconstructing images of subsurface flaws and variations in bond integrity. The paper also highlights the successful use of laser-ultrasonic shockwaves to evaluate bond strength at the interface between the cold-spray deposition and the substrate.

Importantly, this paper aligns with Tecnar’s ongoing efforts in advancing cold spray technology. In late 2024, Tecnar delivered a turnkey laser-ultrasonic system specifically designed for a cold spray manufacturing cell. This system plays a crucial role in improving the inspection and quality control capabilities of cold spray additive manufacturing processes, ensuring higher reliability and structural integrity in the components produced.