Laser-Ultrasound-Based Grain Size Gauge for the Hot Strip Mill

For several decades, laser-ultrasonic technology has been employed in industry to obtain dimensional information about hot steel products. For example, the deployment of Lut 2.0 has facilitated the online real-time measurement of wall thickness in hot seamless tubes and pipes, by utilizing the non-contact feature of laser-ultrasonic technology.

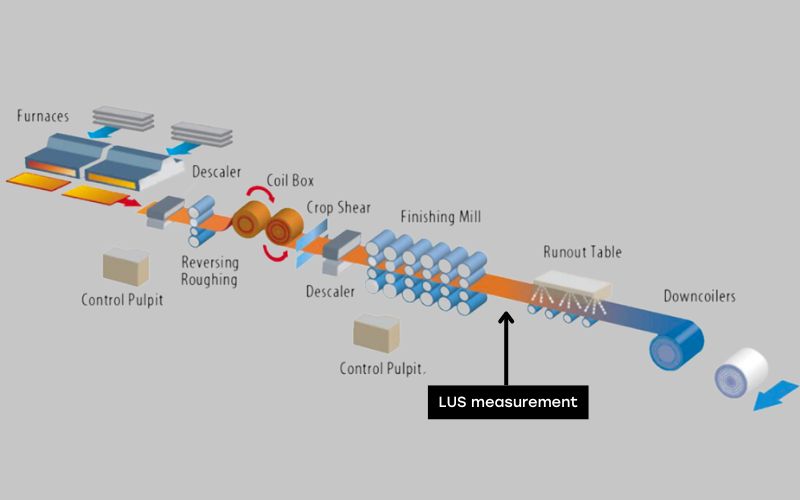

The broad ultrasonic bandwidth inherent to laser-ultrasonics allows for detailed frequency analysis, enabling advancements such as real-time grain size measurement. Previously, such measurements were confined to controlled laboratory settings, typically involving a thermo-mechanical simulator. However, a team led by Mr. Mikael Malmström at SWERIM has recently developed and operated an online grain size gauge using laser-ultrasonic technology for hot steel coils.

In collaboration with EMG Automation, a prototype unit has been successfully installed at SSAB in Borlänge, Sweden. The team’s comprehensive research, published in the journal Applied Science, describes the methodology employed to extract grain size data from laser-ultrasonic attenuation measurements.

The outcomes of their study effectively demonstrate the ability of laser-ultrasonic technology to provide real-time insights into the mechanical properties of produced steel coils. This breakthrough opens up new possibilities for steel producers to enhance control over the quality characteristics of their products.