Laser ultrasound flexible system for non-contact inspection of medium size and complex shaped composite structures made of carbon fiber reinforced polymer

By Jean-François Vandenrijt, Fabian Languy, Cédric Thizy and Marc George, 2018

An advantage of laser-ultrasonic (LUS) compared to standard ultrasonic is LUS’ capability of easily acquiring data from contoured or complex-shaped parts (relaxed normalcy requirement). Back in early 2000, laser-ultrasonics was considered a serious candidate for a broad range of industrial inspections of aerospace carbon fiber reinforced polymer (CFRP) parts. Further development in phased-array sensors and robotics has reduced the need for LUS in such markets. However, there is still a niche for LUS on highly contoured parts.

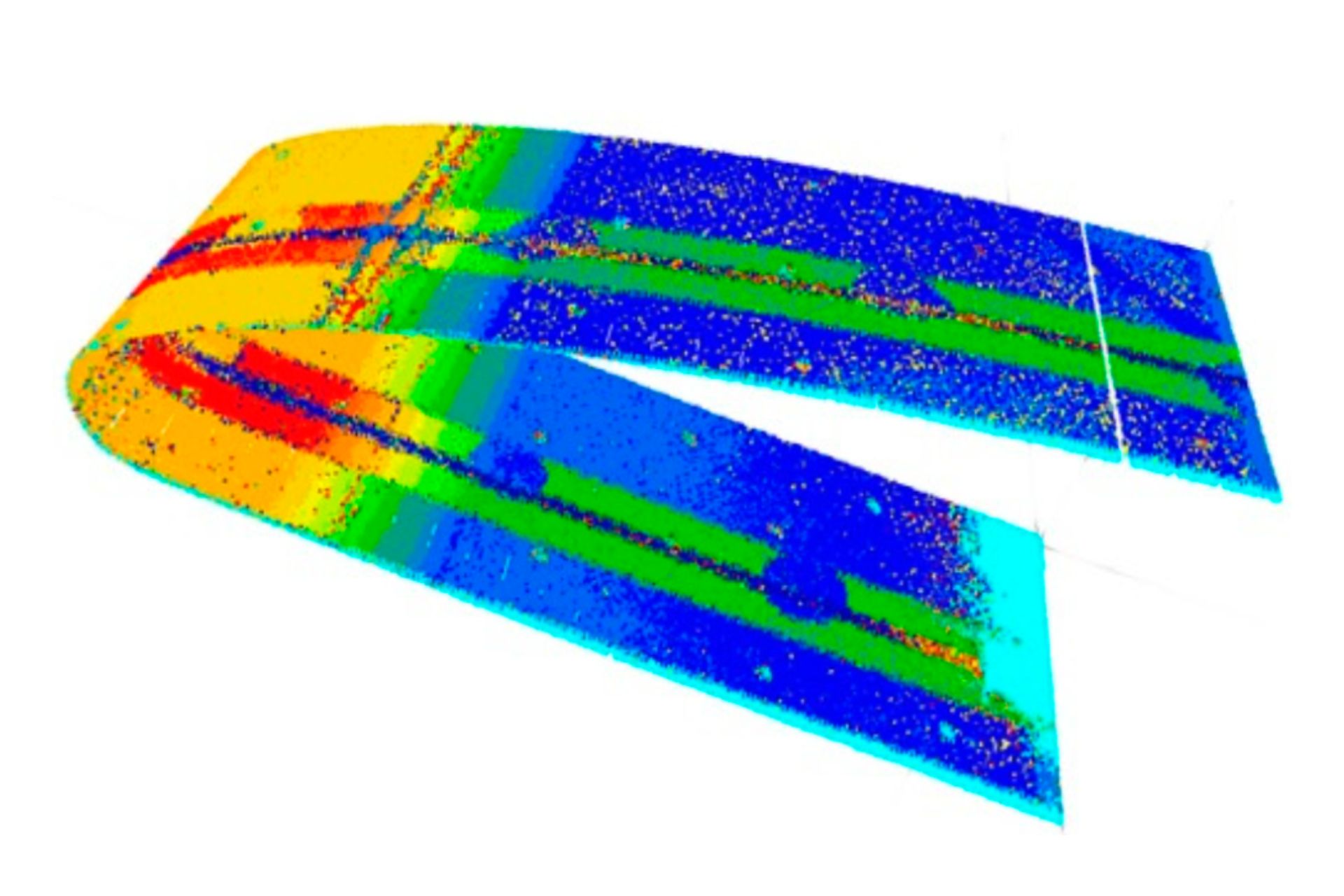

A paper from 2018 by researchers at the Centre Spatial de Liège shows the use of a robotic-based LUS system for the inspection of CFRP aerospace parts. By recording the probe’s position in 3D space for each acquired laser-ultrasonic waveform, a 3D ultrasonic image, known as a C-scan, of the part can be displayed. Such an image is particularly interesting when inspecting a curved shaped part, as shown in figure 5 of the paper. Nice images indeed.

Keywords: laser-ultrasonics, ultrasound, aerospace, composite materials, non destructive inspection