Revolutionizing Aluminum Alloy Manufacturing with Laser-Ultrasonic Technology

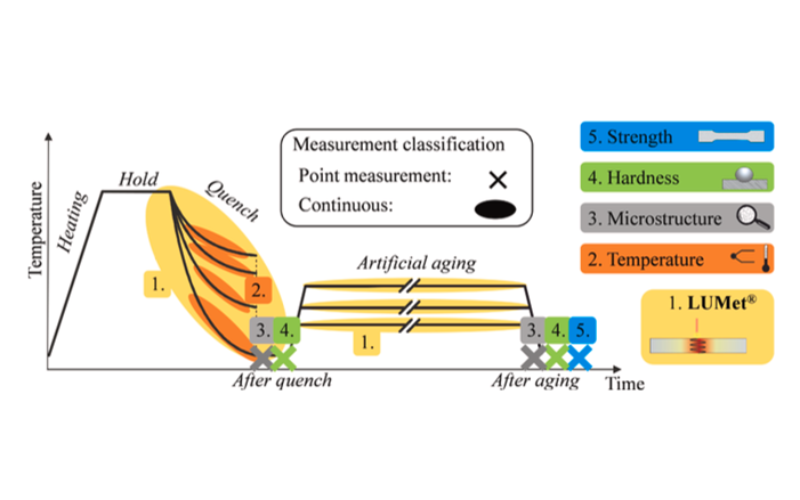

A recent breakthrough by Nikolaos Riga and his team at Friedrich Alexander Universität unveils a novel approach to enhancing the manufacturing of high-strength aluminum alloys. Their research introduces a method for the non-destructive, in-situ detection of microstructural changes during thermo-mechanical treatment, utilizing the advanced laser-ultrasonic system Lumet. This technique represents a significant stride in producing components with complex geometries and tailored properties without compromising strength or quality.

The core of this innovative method is its capacity to observe real-time microstructural behavior under thermal and mechanical stress, a process previously unattainable. By adjusting tool temperatures, the researchers demonstrated the ability to modify the material’s hardness, strength, and ductility, offering a new level of control in aluminum alloy manufacturing. This advancement not only paves the way for the creation of components with specific characteristics but also promotes the optimization of thermal-assisted forming techniques, leading to more sustainable manufacturing processes.

The implications of this study are far-reaching, suggesting a future where the precision and efficiency of aluminum component manufacturing are significantly enhanced through laser-ultrasonic technology. For a more in-depth look at this pioneering research, the full paper is available here This work is a pivotal resource for those in materials science and engineering, highlighting the transformative potential of integrating advanced technologies like Lumet into the manufacturing sector.