Laser ultrasonics for in-situ monitoring of microstructure evolution in steels

By Matthias Militzer, Thomas Garcin, Mykola Kulakiv and Warren Poole, 2013

The advent of new material, in particular of new steels for lighter and stronger automobiles, is pushing for a

better understanding of the relationship between mechanical properties and the internal micro-structure

of materials, and, more importantly, on how to achieve such desired microstructures. Ultrasound has

long been used to investigate the internal structure of materials.

Laser-ultrasonics, with its non-contact feature and broad ultrasonic bandwidth, is to perfect tool to study

the impact of external variables such as temperature and stress on the inner structure of materials. Tecnar

has designed the Lumet for easy integration of a laser-ultrasonic system to thermo-mechanical simulators,

such as the Gleeble. The purpose of the Lumet is to help metallurgist to do real-time monitoring of events

without the need for extensive knowledge in laser-ultrasonics.

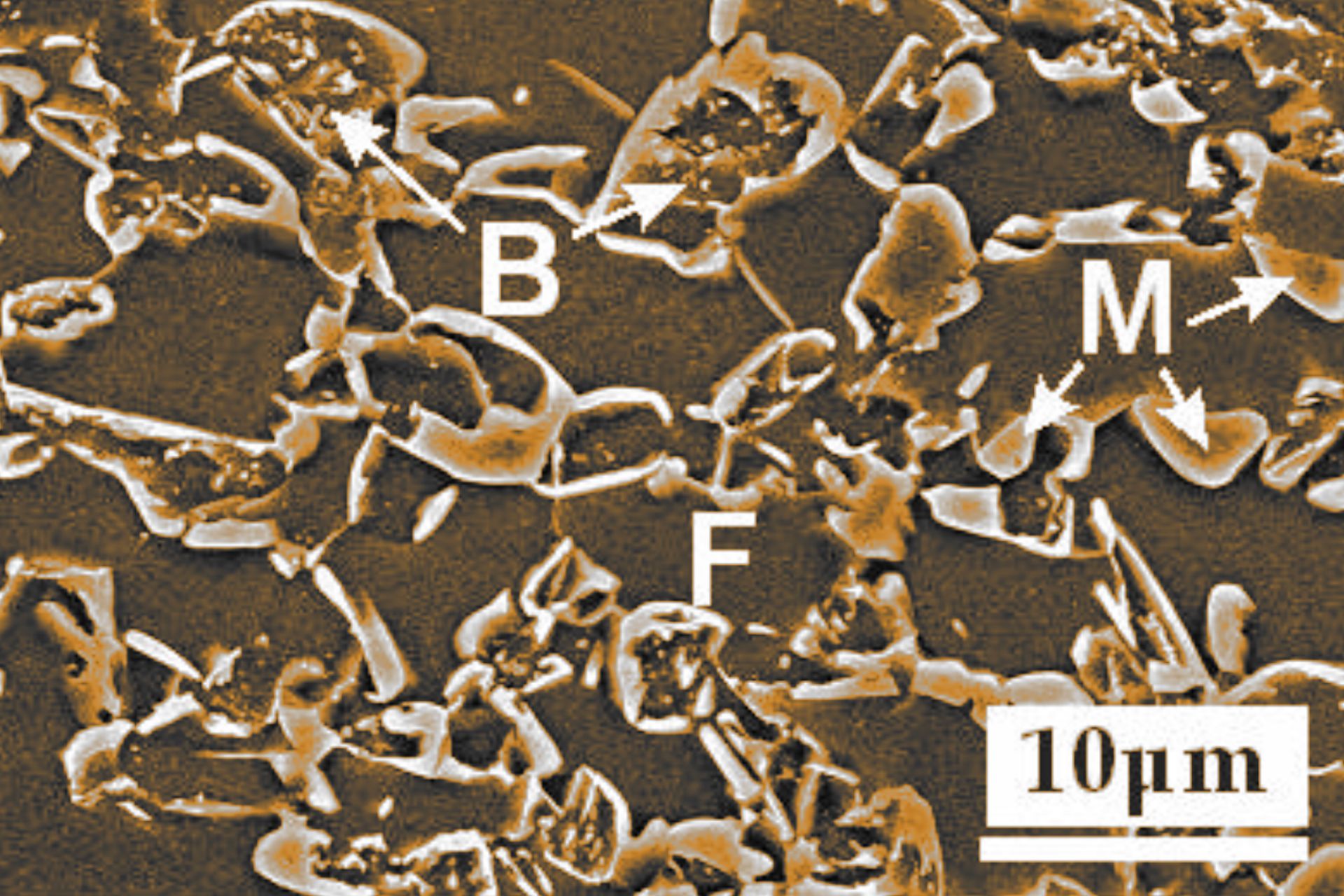

The 2013 paper by Matthias Militzer’s group at the University of British Columbia shows a few applications

of the Lumet for different metallurgical studies. The paper presents results for austenitic decomposition

kinetics of API-X80 steel, ferrite recrystallization in cold-rolled DP600 steel, and grain growth in simulated

heat-affected zones of dual torch welding in API-X80. The group has published several additional papers

since the first commercial Lumet was installed at their site, back in 2012.

I hope this paper gives the reader new intuitions on how to expand their metallurgical studies and consider

new experiments and test runs that are possible with the Lumet.